EN

EN

Products

Product Lineup

This is a molten aluminum quality inspection system that enables quick and highly accurate quality measurement in front of the furnace.

The cleanliness of molten aluminum can be quickly checked on site for degassing effects before pouring molten metal into casting equipment.

BB tester: 800W x 550D x 1150H (mm) 150 kg”

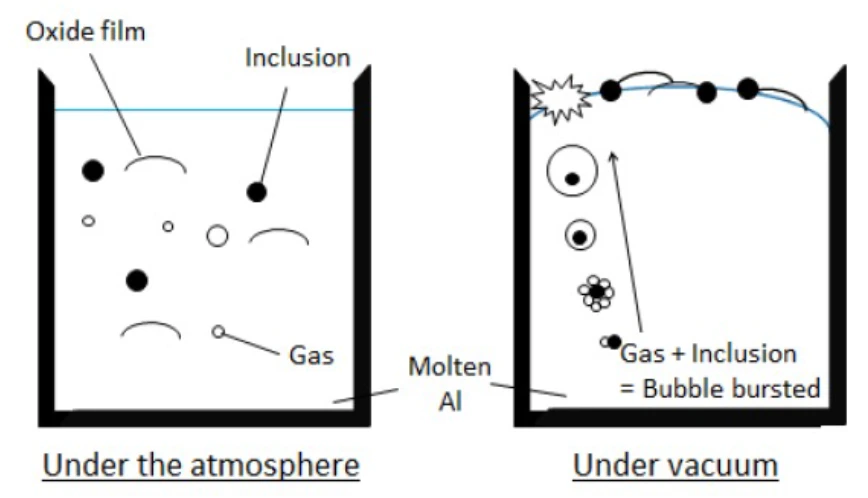

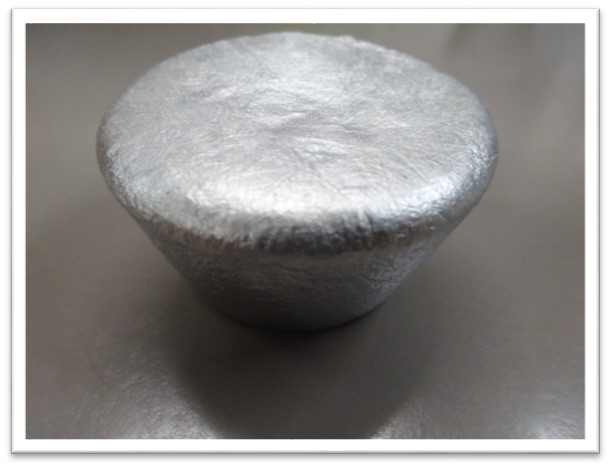

Vacuum evacuation is performed to expand and raise oxides and inclusion in molten aluminum. The amount of inclusion is measured as the change in pressure when the gas attached to inclusion bursts at the surface of the molten.

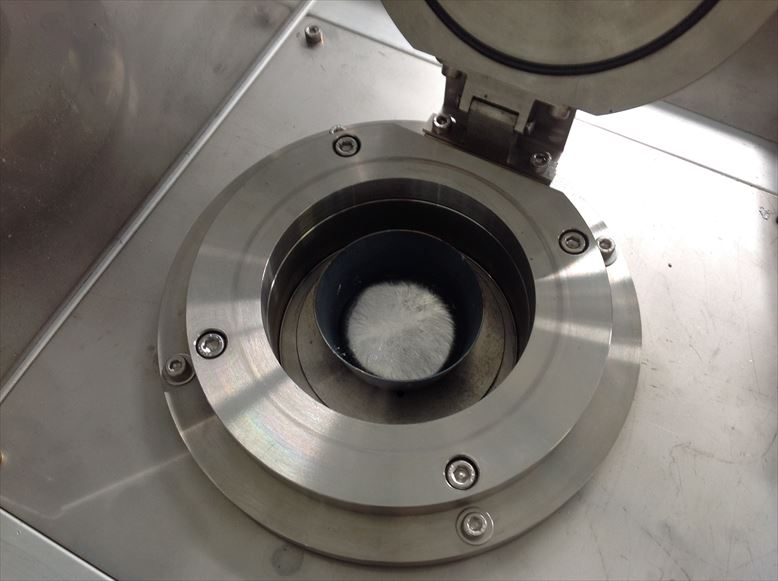

The amount of inclusion is measured by placing about 100 g of molten aluminum in a cup inside a vacuum chamber.

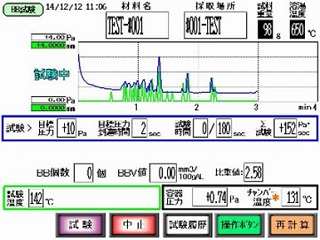

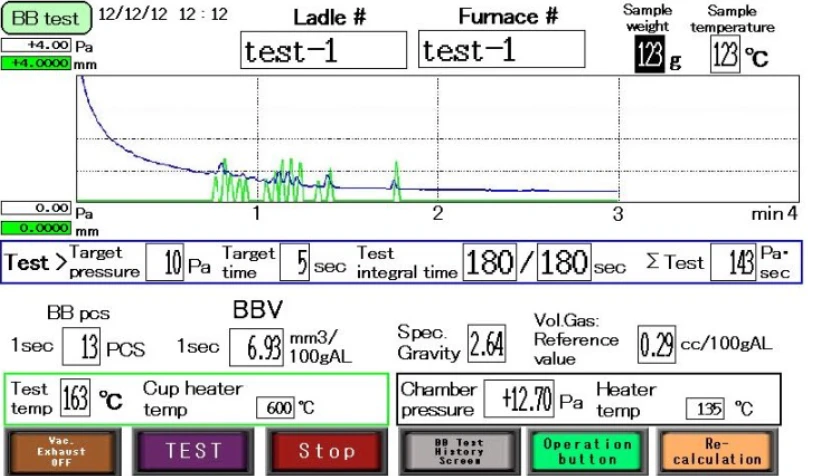

Sample and measurement screen example (burst bubble measurement mode)

In case molten include many inclusions… the sample surface is swollen and numerous ruptures are detected.

In case molten include few inclusions… the sample surface is flat and no rupture is detected.

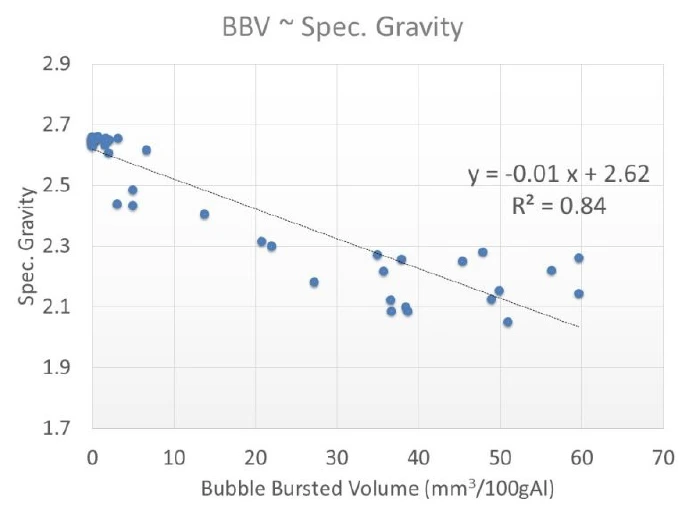

The burst bubble volume measured by the BB tester indicates the degree of bursting that occurred during the depressurization test. Bursting bubbles can cause gas pore defects.

The measured burst bubble volume has a strong correlation with the specific gravity of the solidified sample (left figure).

Left Actual measurement data

Molten metal type: ADC12

Measurement start temperature: approx. 620°C

Measurement time: 180 sec.

In addition to burst bubble measurement, the BB tester is equipped with a “total gas volume measurement” mode.

It measures the volume of gas released from the sample during the measurement.

All operations are displayed on the touch panel. Interactive operation makes it easy to use.

Measurement data is automatically saved in the built-in CF card.