EN

EN

Products

Product Lineup

Degassing mixer is a device used to degas molten aluminum by bubbling inert gas into the molten metal.)

It is used in combination with flux, as the oxides are efficiently removed by adding flux and agitating with a mixer

It cleans molten metal to the new ingot level and contributes to cost reduction. It is used by attaching it to degassing equipment.

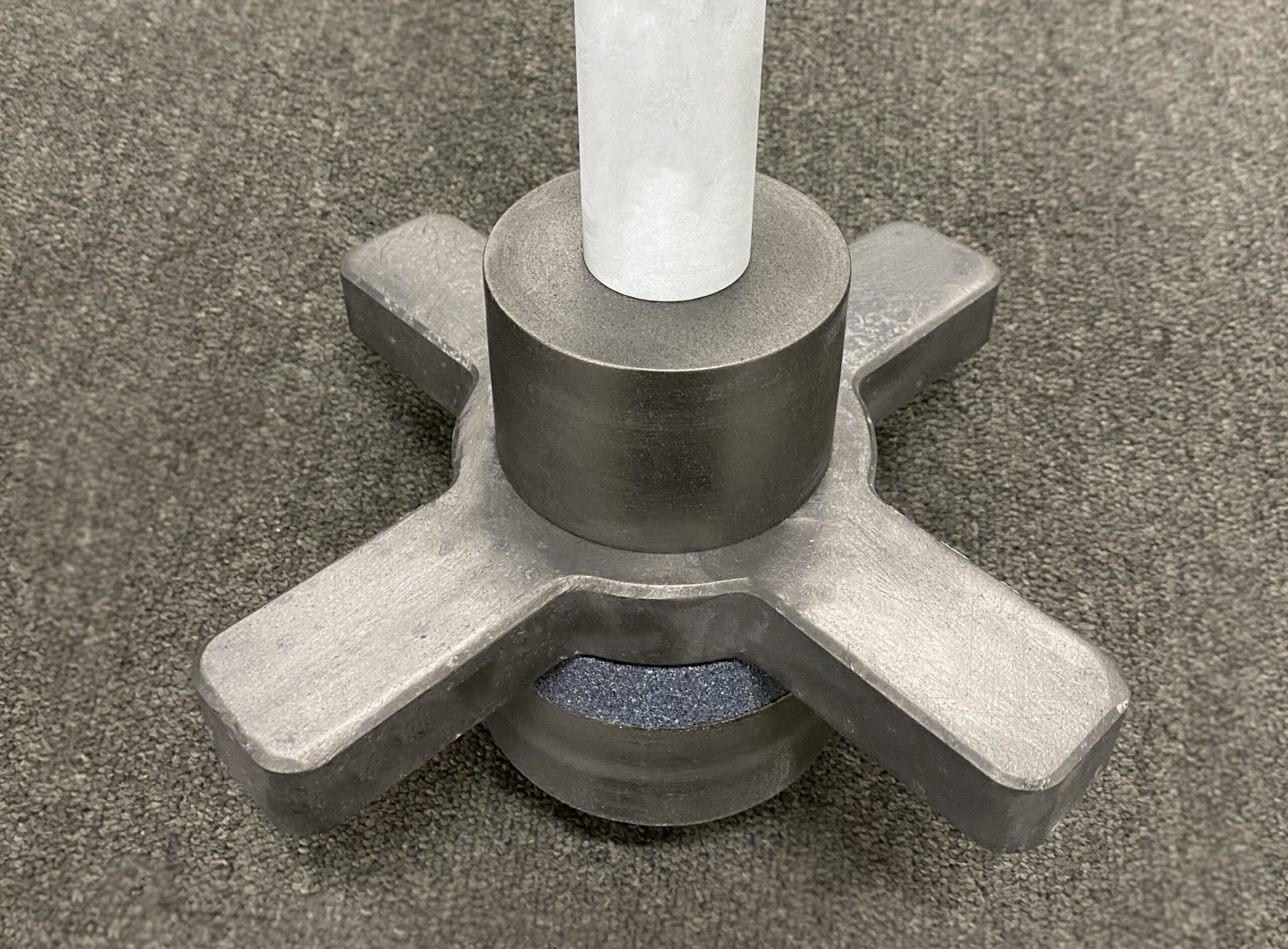

This is a semi-custom degassing mixer.

We manufacture mixers upon receipt of dimensional drawings of the overall length and flange (mounting area) or the actual product.

Maximum dimensions: Shaft φ80 x 1000, impeller φ240

Delivery time: 1 to 2 weeks

Applications:

Ladle Furnace, continuous degas tank, hand-held furnace

Process gas:

Ar/N2 30L/min (0.3MPa)

Mounting flange:

EG type (PCD110 6-φ11)

Materials and dimensions

Shaft: Sialon (φ55-1200)

Impeller: Super Sialon (φ240×40 8 blades)

Application:

Continuous degas tank, hand-held furnace

Process gas:

Ar/N2 10-20L/min (0.4MPa)

Mounting flange:

EG type (PCD110 6-φ11)

Materials:

Carbon (adapter, impeller, screw nut), Sialon (shaft), High Alumina (porous ring)