EN

EN

Products

Product Lineup

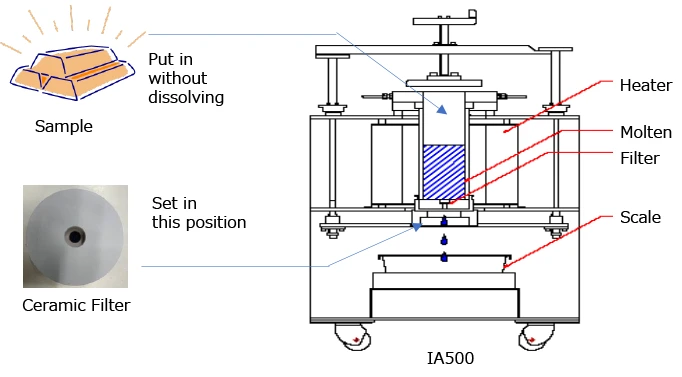

The filtration time allows comparison of the relative cleanliness of aluminum alloys.

There is a concern that oxides and oxide films may form when molten metal is hot-charged in front of the furnace due to the reaction between the molten metal and the atmosphere, but the IA5000 melts quietly in the crucible inside the equipment, so the risk of changing the history of the sample is extremely low.

The filtration time and weight are output as test results.

The results can be taken out of the device via USB.

Inclusion testing is available as an option by sending the filtered filters to us.

Inclusion analysis is performed by measuring the amount of inclusions and analyzing the metallographic structure to provide more detailed information to the customer.