EN

EN

Products

製品情報

Product Lineup

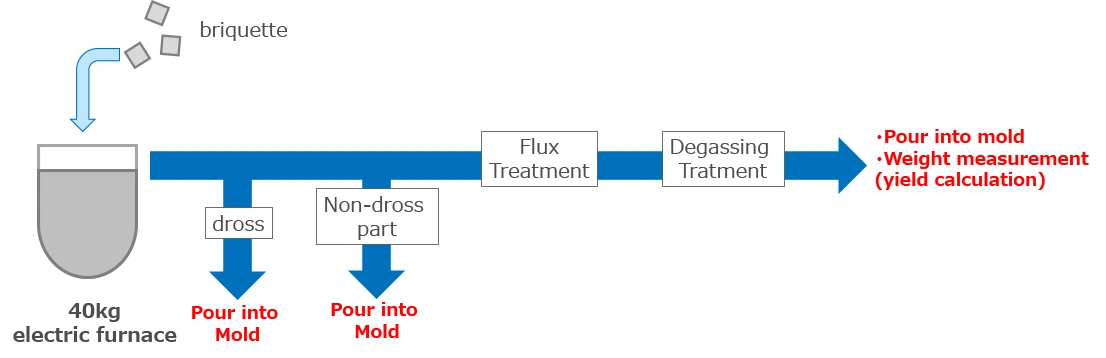

Nikkin’s testing services can help you with a variety of requests, including the following:

We will assist you from test plan through web conference.

(*) is our original test

Temperature: 630~850℃

Shape: Powder

Type: With Na or without Na, completely free of toxic and hazardous materials, etc.

Temperature: 660~790℃

Shape: Powder, tablet

Temperature: 650~

Shape: powder

Type: Ti, Ti/B, Zr added

Temperature: 700~760℃

Shape: powder

Type: Mg and Ca removal

Shape: Bar shape

Type: Mg90%, Al10%

Shape: pudding shape, bar shape

Type: Sr10%, Sr10

Temperature: 680-800°C

Shape: Bar shape

Type: Ti5%, B1