EN

EN

Products

製品情報

Product Lineup

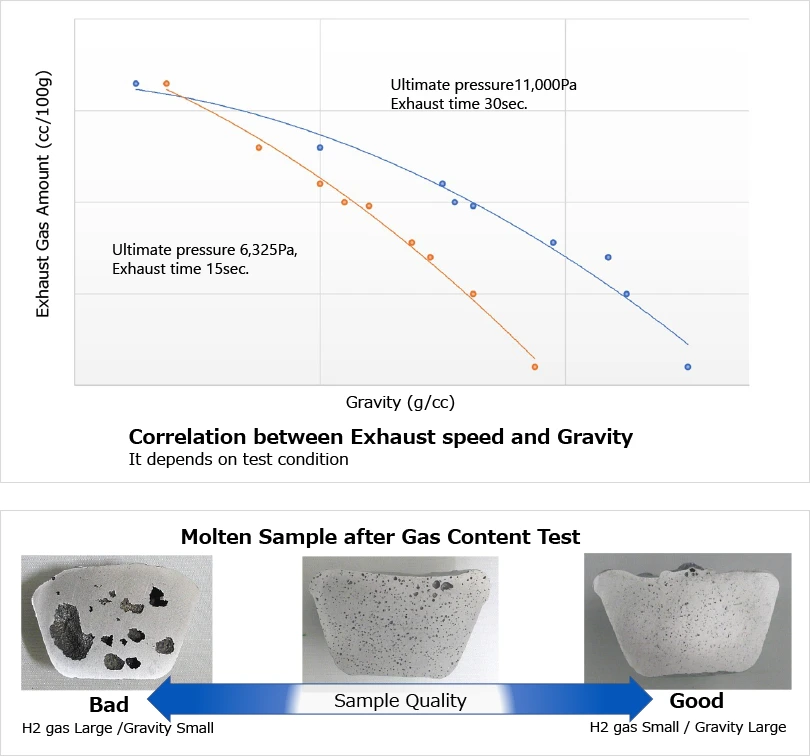

This product is a decompression coagulation measuring device for simple measurement of gas in molten metal. Sample quality is determined by specific gravity.

In the case of high-grade aluminum castings, problems such as pinholes are always present as surface defects of the product.

In on-site management, it is very important to know the amount of gas in the molten metal before casting starts in order to treat the molten metal in the subsequent process.

This is a sample after the depressurization solidification test.

The specific gravity value of the depressurization solidification test depends on the amount of hydrogen gas exhausted.

By adjusting the depressurization conditions, NK1700 can perform tests under conditions that correlate well with the failure rate of your products.