EN

EN

Technical Information

Aluminum is very active, and its cleanness effects the percentage of defect product directly. So our company has improved the technology for treating molten metal and keeping them clean, since its foundation in 1956. Below is a brief explanation of our technology.

Molten aluminum contain not only an alloy, but an oxide, an intervening substance, hydrogen gas and an alkali metal. To remove the impurities, Flux is used in general. Flux can adsorb the substance which could cause defect, and remove them from molten metal. We can provide various flux lineup according to purposes and properties of molten metal.

The method of adding flux is also important for the quality improvement of molten metal. Even if you add the flux and agitate manually powered, you can obtain a certain of effect. However it may happen some defects such as low reaction efficiency and smoke generation. Thus we manipulate apparatus for injecting flux into molten metal by using inert gas as carrier. Flux Feeder allow to improve the reaction efficiency and prevent smoke.

Aluminum alloy flux consists of alkali metal(ex.Na, K), alkali earth metal(ex.Ca, Ba, Mg), aluminum, chlorine compound(ex.Si) and fluorine compound.

Degassing Treatment remove hydrogen gas which is generated in melting process and mixed in the molten aluminum. In order to prevent shrinkage cavity defect, the gas need to be taken away.

By inserting inert gas with Degassing Equipment, hydrogen gas can be removed ffectively. Gas partial pressure help to absorb Hydrogen gas.

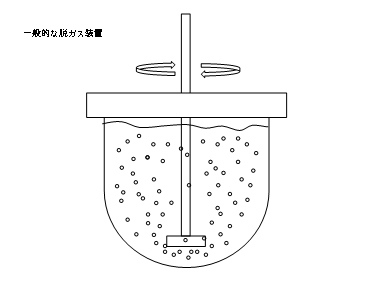

Below is the general structure of the equipment. Inert gas is spread into entire molten metal by rotating mixer without waving the surface of molten.

Determining the accurate results of molten aluminum processing is important for product quality control.

The conventional method is mainly based on visual inspection. However, this method is susceptible to human factors, which can lead to inconsistent judgment results.

Therefore, a dedicated high-precision inspection device is necessary to control molten metal quality. We measure the results of molten metal processing with various inspection methods according to the purpose.